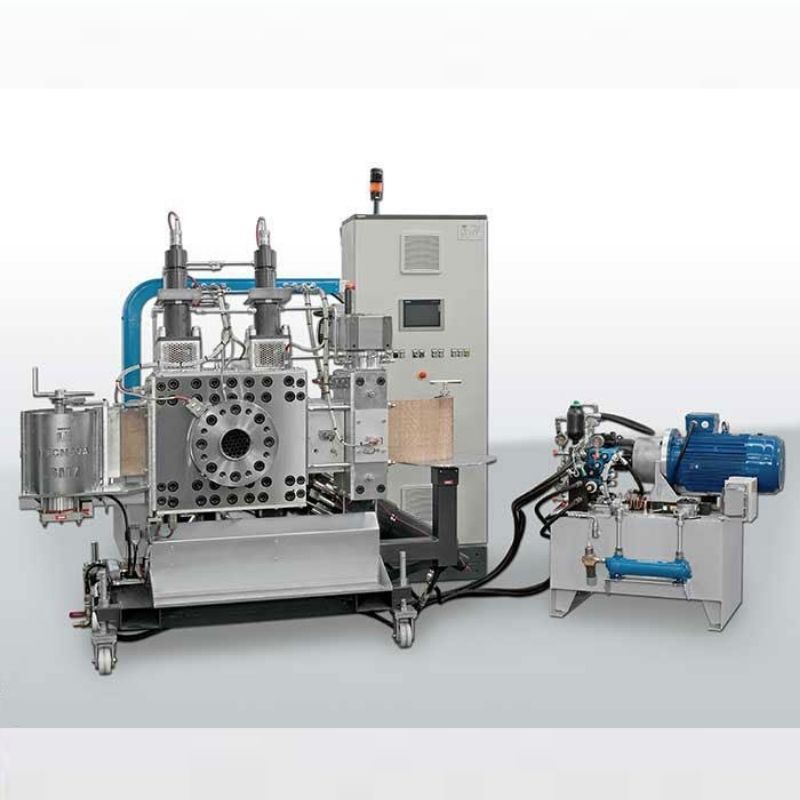

The automatic screenchanger model “3M7” can be used for several applications: compounding, pellets, post-industrial and post-consumer recycling and agricultural film.

The filtering element is a mesh belt available in different sizes and different filtration ranges, up to 80 micron.

It guarantees high regranulate quality at low operating costs and a fully-automatic process.

The system principle lies in its continuity. The new TECNOVA 3M7 guarantees uninterrupted melt flow without any significant pressure peak during screen changings. The material normally flows through a melt channel which has a screen belt filtering impurities.

Anytime the pressure value reaches the set threshold, the screen change process starts, the dirty section is replaced by a clean and fresh one. The whole cycle lasts about 20 seconds.

Some major benefits:

- High filter fineness possible, up to 80 micron;

- Extruder operation during filter band feed;

- Fully automated filtration;

- Very low operating costs;

- reduction of energy consumption;

- almost zero polymer loss during cleaning cycle;

- minimize material waste;

- reduction of personnel involved;

- recycle highly-contaminated plastics;

- reduce extrusion system downtimes;

- reduction of maintenance interventions;

- increase extrusion system throughput and production rates;

- 24/7 production, with no interruptions or downtimes.

Reviews

There are no reviews yet.