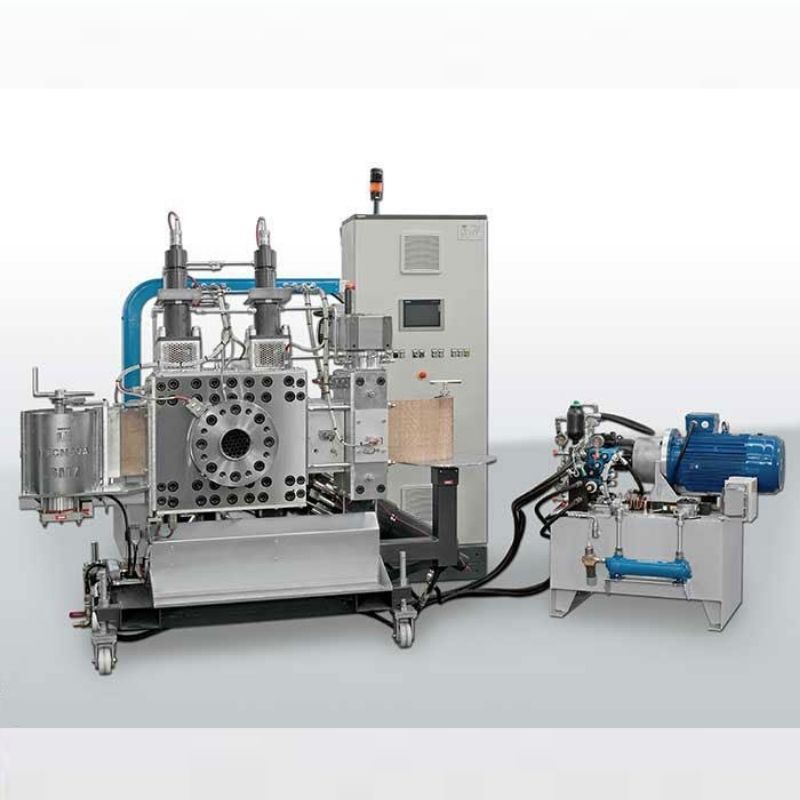

TRUE ALL ELECTRIC TECHNOLOGY

Precise • Efficient • Fast

The NOVA eT are 5-point double toggle clamp, all-electric injection moulding machines available in 50-, 80-, 100-, 130-, 180-, 220-, 280- & 350-tonne models. Injection capacities from 22g to 1405g (PS) across the range. These all-electric injection moulding machines offer energy savings of up to 80% when compared to conventional hydraulic drive solutions, and substantially reduced cycle times due to fully overlapping movements. NOVA eT machines are equipped as standard with:- ETHERNET VARAN PROTOCOL control system

- Smart Flex 2 clamping unit with generous tie bar spacing to accommodate larger moulds and a moving platen that rides on linear bearings for excellent platen parallelism and reduced energy use

- Robust ball-screw injection drive system with high speed, high load ball screws

- Multi touch screen TACTUM based user interface with full range of control parameters

- Ready for AMICO 4.0 ™ wireless remote service access

Reviews

There are no reviews yet.